Groove grinders

Strong performance and longevity for highest efficiency

Herkules groove grinders combine a number of advantages. The machines' longevity and their top performance guarantee their success in your production facility.

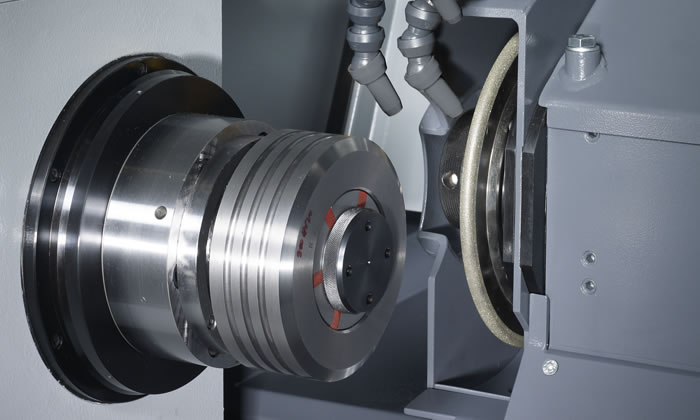

Quality down to the last detail – all machine components consist of very stable cast-iron elements with excellent damping properties and a high rigidity for nearly vibration-free machining. Minimized set-up and machining times are also characteristic for Herkules groove grinders. The hydraulic clamping device is integrated in the main axis and allows for an absolutely accurate changeover of workpieces within seconds. This minimizes typical non-productive times for changing tools. The generously dimensioned grinding spindle, which is mounted radially and axially entirely free of play, reduces grinding times significantly.

Efficient groove grinding

The design of our groove grinders is the result of many years' experience gathered by Herkules in manufacturing first-rate roll grinders and lathes. Guideways and bearings have been developed according to the latest technological developments and optimized with a view to longevity and ease of maintenance.

Technology

|

Options

|