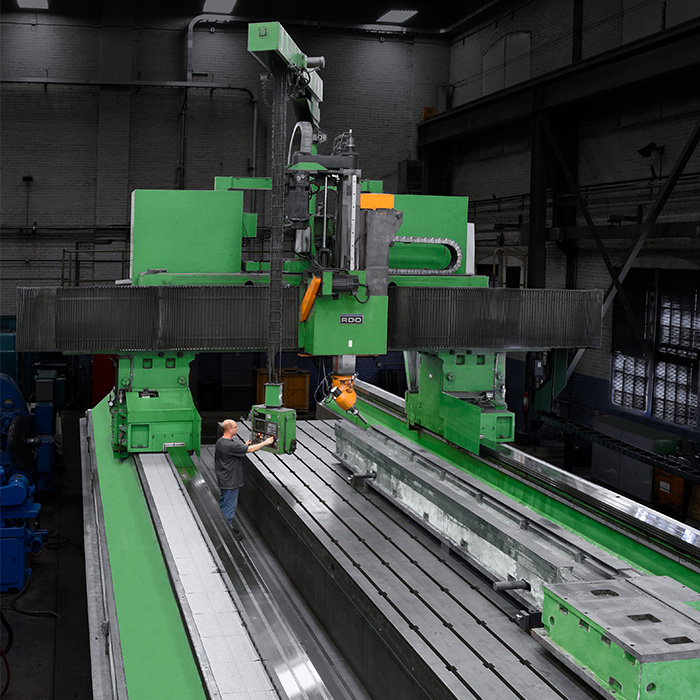

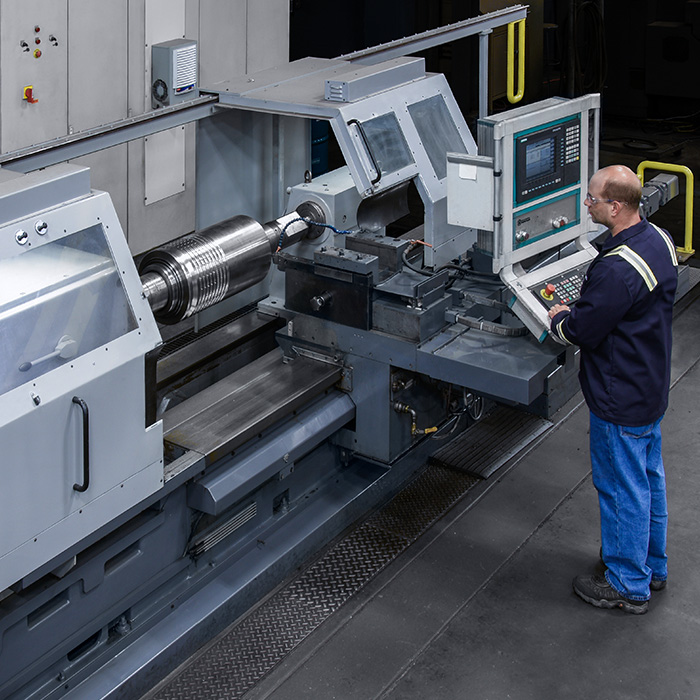

Absolute precision, individual services and quality performance – Herkules USA offers a great variety of large machining services for your individual applications. Values such as quality and efficiency have been characteristic features of Herkules machines for more than 100 years.

State of the art equipment and a skilled team of machinists guarantee high quality craftsmanship and excellent machining work. Herkules is experienced in managing complex machine projects thanks to our large variety of machines and tools. Our modern workshop is dedicated to producing core products and components for HerkulesGroup machines of all kinds. This shows our ability and knowledge to take on external production orders with specific needs and problem situations.

In all regards to large scale CNC machining projects you will find a reliable partner in Herkules with comprehensive machining capabilities and know-how.

You need help for your specific problem situation or machining challenge? Our service team is here to help you. You can contact us at 1-724-443-8900 or send your inquiry to info@herkulesusa.com and we will work on your individual project.