American companies rely on Herkules quality

Current orders from Neo Industries, U.S. Steel and Logan Aluminum

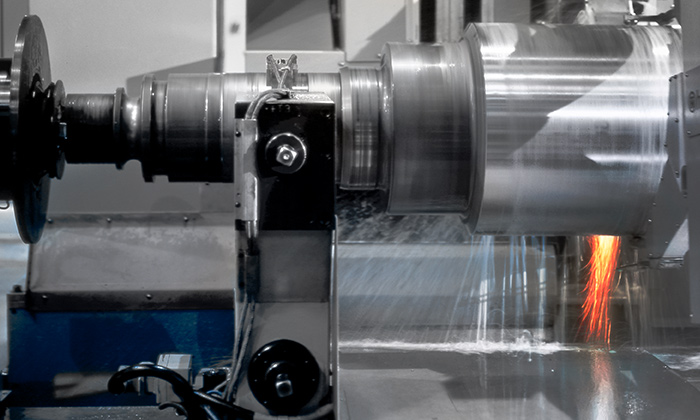

Our American customers have the highest demands on roll grinding machines. Herkules is able to meet these special requirements with its high-precision machines. Herkules roll grinding machines offer all users the highest level of precision and performance. Based on various current orders, you can get an insight into the range of services offered by Herkules.

Roll grinder with high-precision measuring controls for Neo Industries

The American contract grinder Neo Industries LCC, Inc. has purchased a WS 450 × 5500 CNC Monolith™ for its service center, which was recently installed at the customer's plant.

Thanks to the future-oriented Monolith™ machine beds, vibrations that occur are effectively dampened and the technology guarantees homogeneous roll surfaces. The inherently rigid construction, the thermostable properties and the foundation-free placement directly on the shop floor offer the customer clear advantages. Equipped with high-quality measuring systems such as C-Frame/C-Caliper, Creeping Wave and Eddy Current measurement system, machines from Herkules offer Neo Industries excellent quality and reliable precision in grinding results.

U.S. Steel Corporation for Granite City Works acquires Herkules machine for its hot strip mill

How do you completely convince a customer? When quality and performance are satisfying. KPM, the revamping specialist of the HerkulesGroup, is already known to the U.S. Steel Corporation. The HerkulesGroup Company was commissioned in April 2019 to modernize a Farrel machine, which was successfully completed in November. This is where Herkules comes into play: Apparently, KPM left a lasting impression, so that in the future the U.S. Steel Corporation will also place its trust in a roll grinding machine from Herkules.

After the installation in the summer 2020, the WS 600 × 600 CNC Monolith™ will be used to process the hot strip mill rolls at the company's plant in Granite City. The roll grinding machine is equipped with fully integrated measuring systems. The measuring systems offer real-time processing and analysis: During the grinding process, data is collected and directly evaluated. The control values are adjusted “on the fly” during the process in the control. The U.S. Steel Corporation can be sure that a Herkules machine and services from the HerkulesGroup can fully meet their requirements.

Logan Aluminum uses roll grinders with Monolith™ machine bed for its demanding rolls

The advantages of the Monolith™ technology are unbeatable. As a longstanding customer of the HerkulesGroup, Logan Aluminum Inc. intentionally chose a Herkules roll grinding machine with a patented Monolith™ design.

The U.S. based aluminum hot and cold strip producer acquired a WS 600 × 6000 Monolith™ in mid-2019, which will be delivered to the customer's plant in September 2020. But not only that: in addition to the advantages of the foundation-free Monolith™ bed, the customer benefits from fully integrated HCC/KPM measuring systems like Eddy Current or Roughness Scattered Light Detection. Highly precise results, the latest technologies - with a machine from Herkules, Logan Aluminum has all the advantages on its side.