Machining Center

Taking productivity to the next level

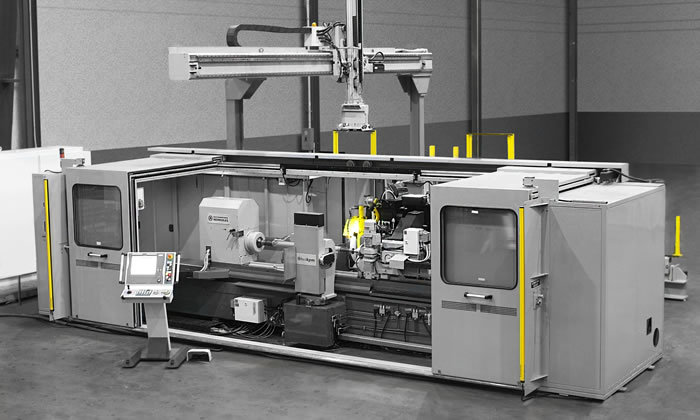

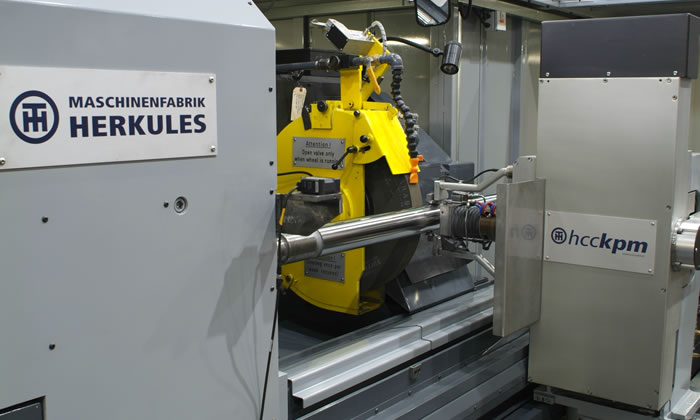

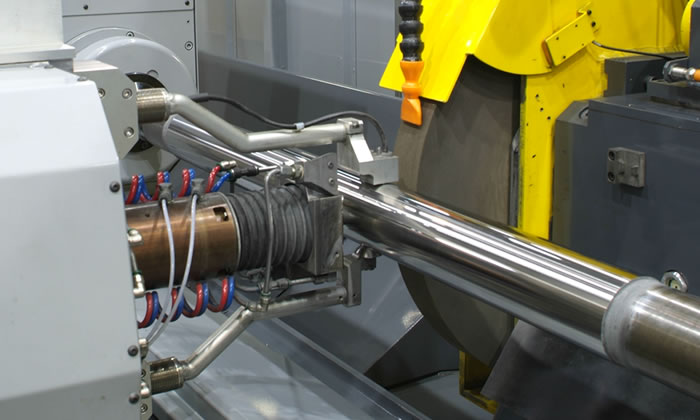

Maximum productivity, highest machining quality, full automation – these advantages are compelling arguments in favor of the roll machining center engineered by Herkules. The innovative machining center consists of a grinder and an integrated loader for automatic loading and unloading of rolls including the transport from and to the roll pallet.

Fully automatic, highly efficient roll machining

The integrated control system ensures that machine and loader work together smoothly and allows for fully automatic machining of all workpieces on a pallet successively in one single program. Due to its compact design the machine loader requires minimum installation space only. The machining center is tailored to your specific requirements with numerous equipment options, such as the proven HCC/KPM measuring and inspection technology.

Options

|

Technical data

|

On request, additional specialized solutions can be implemented for you.