Applications

Ideal solutions for your machining tasks

Quality, precision and efficiency for every application and industry

The Herkules product range comprises various solutions, tailored to your specific application in the areas of roll machining and machining rotationally symmetrical workpieces. Values such as quality, precision and efficiency have been characteristic features of Herkules machines for more than 100 years.

Applications

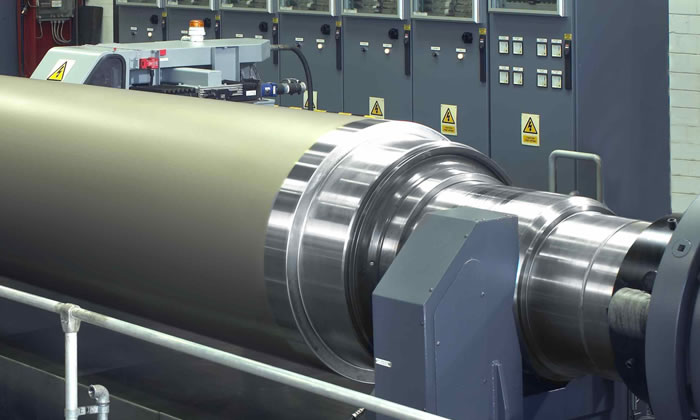

With more than 100 years of experience, Herkules is the specialist in roll machining and a world leading manufacturer of roll grinders. The reason why customers worldwide rely on Herkules for their machining demands: pioneering machine technology combined with solutions tailored to the client’s needs.

Rolls with a weight of up to 260 t, a length of 18 m and a diameter of 3 m can be processed to the highest quality standards. Thanks to a modular system and a wide range of optional equipment available, the grinding machines can be used in all industries. Herkules roll grinders are available either as table type machines with a traversing workpiece or with a traversing grinding saddle.

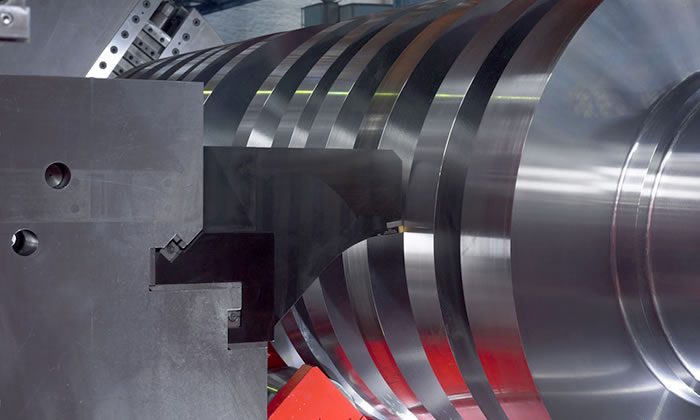

Turning large workpieces is a highly demanding application for a machine tool. Along with highly precise processing, the focus is on sturdy design, reliability and longevity of the machine. Producers of rotationally symmetrical workpieces, such as forges or roll manufacturers, achieve the highest efficiency with lathes by Herkules. The integration of milling heads, logo milling units or other optional equipment allows for the performance of very complex machining tasks in one single setup.

With its NWD series, heavy-duty lathes with hydrostatic guidance systems, and the smaller lathes of the P-series, Herkules offers customized machines for the processing of, for example, section rolls, forged shafts or rotors with a maximum of precision.

Textured rolls are essential for the production of sheet metal products which have to fulfill the highest quality standards regarding moldability and paintability, such as those used in the automotive or the packaging industry.

The Herkules portfolio comprises texturing machines for the efficient machining of rolls, ranging from a few hundred rolls to over 1,000 rolls per month. Produced with an emphasis on high uptime and productivity, the texturing machines ideally complement your Herkules roll shop.

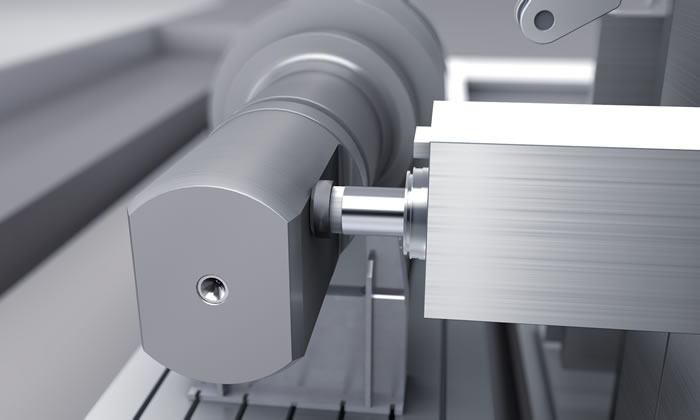

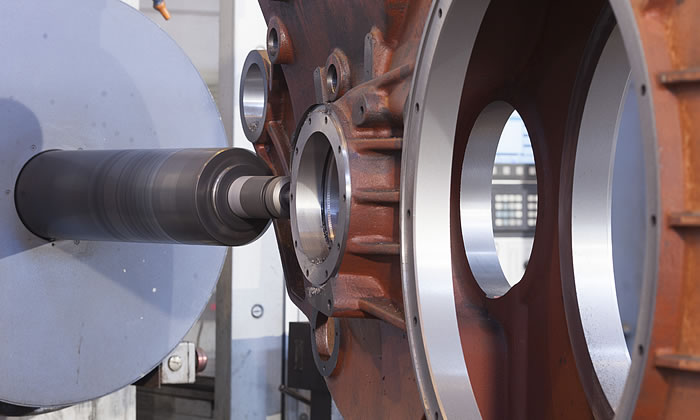

UnionChemnitz, a HerkulesGroup company, is a manufacturer of boring mills which specialize in the machining of roll necks. The planer type boring mills PCR 160 are equipped with special clamping solutions for handling rolls (roller guides), manufactured by Herkules.

Thanks to the broad range of milling units and tools, these machines are able to meet any demand – the most diverse types of roll necks can be machined with high precision and efficiency. Together with the customer, the well-experienced staff at Herkules and UnionChemnitz develops customized machine solutions for this application.

Notch milling machines by Herkules are the perfect solution for manufacturing rebar. They are characterized by a machine concept which guarantees extreme stiffness. That ensures high productivity even with very hard materials. Notch milling machines made by Herkules have been an integral part of many roll shops around the world for many decades.

Herkules also offers lathes and groove grinders equipped with a notch milling unit. Modular machine concepts with an integrated notch milling device allow for high flexibility in the complete machining of rolls and roll rings in a single set-up.

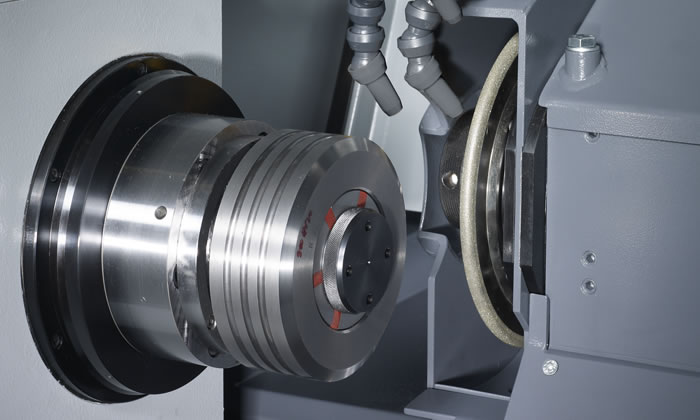

When manufacturing wire, bar steel and rebar, the highest quality standards apply regarding precision and surface quality of grooves in rolls and roll rings, especially in finishing stands. In order to machine rolls and roll rings efficiently and economically, tight tolerances have to be met.

The solution: groove grinders made by Herkules. Using deep pass grinding and contour grinding for grinding grooves in carbide rings achieves the highest shape accuracy and surface quality in very short machining times.

Many manufacturers of long products use their logos to brand their products. Individualized products raise the value of brand recognition in the market.

Lathes, notch milling machines and groove grinders by Herkules are available with logo milling devices fully integrated into the machine control. Using these, complex, customer-specific logos can be placed on the rolling material.

UnionChemnitz, a HerkulesGroup company, is the only German supplier to offer boring mills covering the complete range of 110 to 260 mm spindle diameter – with linear or fully hydrostatic guideways – as well as a wide range of travelling column mills. Thanks to a comprehensive range of equipment, the machines cover many applications.

The horizontal boring mills in floor-plate design provide the utmost precision during finishing operations, and at the same time allow powerful heavy-duty cutting during roughing operations. The travelling column mills of the MILLFORCE series combine fast and exact positioning of the milling heads with excellent stability. The available milling units can be changed automatically with a pick-up station. Thanks to this optional pick-up station, the application options of the travelling column mill are expanded considerably.